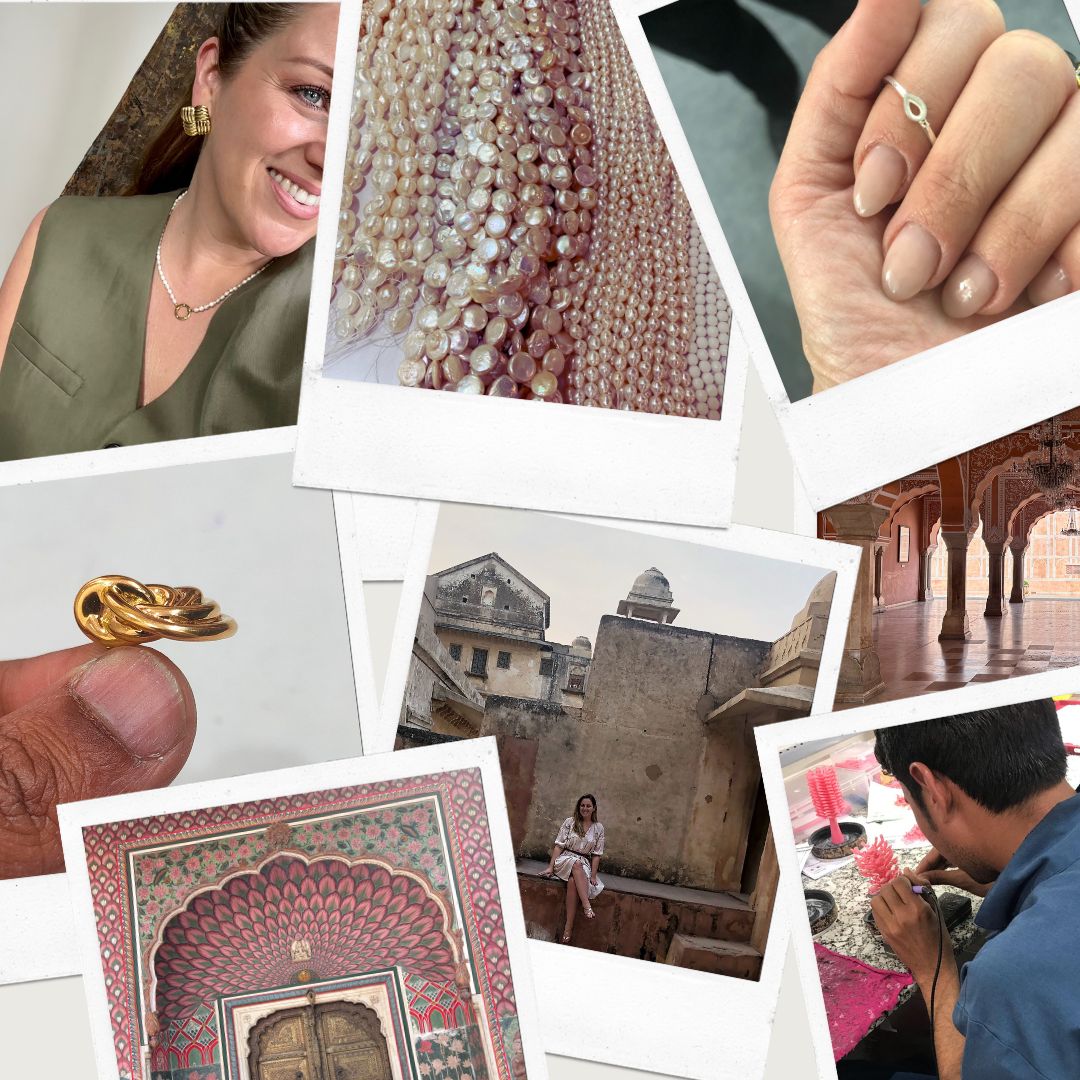

The Making of: Behind the Scenes

Here’s a behind the scenes look into how our beautiful pieces are created from design through to being ready to wear! Each handcrafted by our amazing, talented artisans in Jaipur, India.

The care that goes into our jewellery is unmatched because we want you to love your CE pieces just as much as we do...

Carrie x

Handcrafted Jewellery: The Process

Design & 3D Model

First things first! Each piece is designed by our in-house team and then digitally brought to life by our experts in Jaipur India.

Rubber Mould

A 3D model of the designed piece is then printed and is used to create a rubber mould.

Wax Moulds

The rubber mould is filled with wax and then multiples of each piece are created. Each wax piece is checked and filed to remove any imperfections created by the wax moulding process.

Jewellery Mould Tree

Each wax piece is then added to a tree ready to be transferred into plaster to create a mould ready for casting!

Casting Process

Once casted, the wax is slowly melted to leave an impression in the plaster before being refilled with molten metal.

Plating Process

The metal pieces are then removed and it’s time for plating! During this process the pieces are tested to ensure they have the correct microns of gold.

Polishing Process

Final filing and polishing then takes place to make your jewels sparkle! Gemstones are often also incorporated at this stage.

Quality Check

The last step is quality control, where each piece is inspected to ensure its up to CE standard!

Ready to Wear

Ta da! And like magic your favourite jewellery is ready to be styled by you!

Our diamonds, gemstones, and metals are all ethically sourced and produced. The quality of CE is extremely important to myself & my team, so we work closely with our jewellers & artisans to ensure that the best materials, processes and practices are used for every piece!

Carrie x